-

2022-10-12 What is a diaphragm compressor?

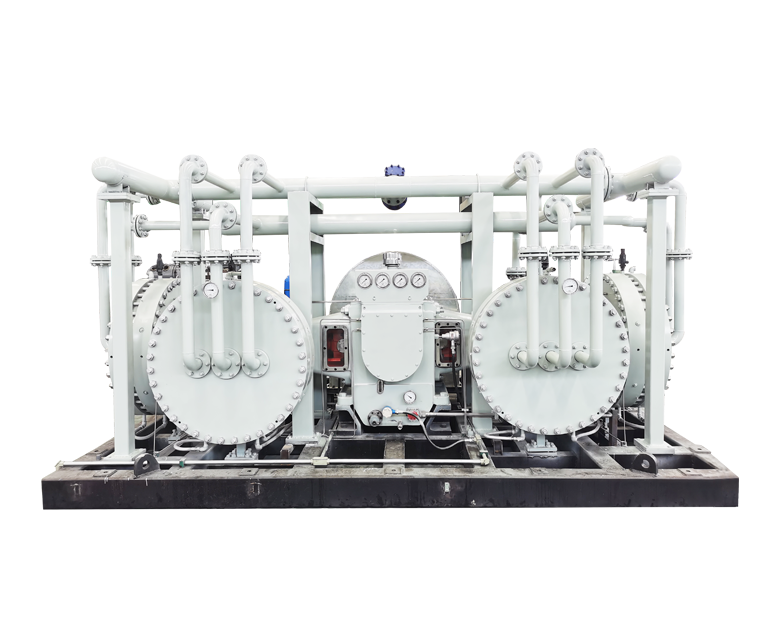

2022-10-12 What is a diaphragm compressor?Diaphragm compressor is a reciprocating compressor that compresses and delivers gas by reciprocating the diaphragm in the cylinder. A reciprocating compressor that compresses and delivers gas by reciprocating the diaphragm in a cylinder. The diaphragm is clamped by two restriction plates along the periphery and forms a cylinder. The diaphragm is driven by mechanical or hydraulic means to reciprocate inside the cylinder, thereby achieving compression and transportation of gas. Compressors that use rubber or plastic diaphragms and are mechanically driven are only suitable for situations where the displacement is a few cubic meters per hour and the displacement pressure is around 1.2 megapascals. They are generally made as single-stage or two-stage compressors. Diaphragm compressor is a special structure of volumetric compressor, which has the characteristics of high compression ratio, good sealing, and compressed gas is not contaminated by lubricating oil and other solid impurities. Therefore, it is suitable for compressing high-purity, rare and valuable, flammable and explosive, toxic and harmful, corrosive, and high-pressure gases. Compressors that use metal diaphragms and are driven by hydraulic forces are quite common, with a displacement of up to 100Nm3/h. The discharge pressure of multi-stage compression can exceed 100 megapascals, making them suitable for transporting and pressurizing various gases. They can also be used as booster compressors after oil-free lubrication compressors. The thickness of the metal diaphragm is generally taken as 0.3-0.5 millimeters. The lifespan of the diaphragm depends on the selected material and its surface roughness. Due to the large motion mass of hydraulic drive, the average speed of the piston in the hydraulic part can only be taken as 2 meters per second, so the speed of the machine is usually in the range of 300-500 revolutions per minute. The ratio of the cylinder working volume surface area to the cylinder volume of a diaphragm compressor is much larger than that of a reciprocating piston compressor, and the compression of gas is close to an isothermal process, so the pressure ratio of each stage can be as high as 25. Suitable for various purposes with small displacement. Used as a small gas supply device, pneumatic regulator, ventilation device for aquarium feeding pools, as well as for the transportation and pressurization of oil-free, toxic, corrosive, valuable, or radioactive gases in the chemical industry.

-

2022-10-12 Introduction to the operating specifications of piston compressors

2022-10-12 Introduction to the operating specifications of piston compressors1. Air compressor lubricating oil, generally speaking, is of high oil quality and contains oxidizing agents, which are not easily oxidized or deteriorated, not easy to foam, and have a low residual carbon content and high flash point. Due to its wide variety, the commonly used ones are: A 13 "compressor oil (winter oil) B 19 "compressor oil (summer oil) 2. Please keep the oil level within the red circle in the middle of the oil mirror. Adding too much oil wastes lubricating oil and can easily cause carbon buildup in the air valve. Adding too little oil often leads to poor lubrication, resulting in burning or wear Therefore, the oil level should be kept within the red circle range at all times 3. When the oil color turns black or there is oil contamination (approximately every 500 hours of use), please change the oil once 4. When changing the oil, please unscrew the oil drain plug under the crankcase first, and use cardboard or other objects to remove the dirty oil. After the oil is completely drained, tighten the oil plug (apply universal glue or anti leakage paste on the oil plug teeth to prevent oil leakage), and then open the oil cap to add new oil to the middle of the red circle on the oil mirror 5. Do not add new oil during operation 6. Avoid using concentrated lubricating oil and other miscellaneous waste oils

-

2022-10-12 Introduction to precautions for piston compressors

2022-10-12 Introduction to precautions for piston compressors1. Check all screws or nuts for looseness 2. Is the tightness of the belt appropriate 3. Whether the pipeline is normal and the oil level is appropriate 4. Whether the wires and electrical switches comply with regulations and whether the boundaries are correct 5. Are the pivot points of each wheel foot fixed or stable 6. Whether the belt pulley can be easily rotated by hand during compression 7. Before the compressor starts working, run it idle for 2 to 3 minutes or more, and then operate it normally 8. Check if the direction of operation is the same as indicated by the arrow. If not, swap any two of the three power supplies for the three-phase motor 9. Air purifiers should be regularly checked for contamination and adhesion, and filter cotton should be removed and cleaned (with air and oil) or replaced regularly to maintain good air filtration efficiency 10. After daily use of the air compressor, the drain valve of the bucket should be opened to remove any accumulated moisture and oil stains from the bucket 11. The cylinder head and copper pipe of the air compressor generate heat due to air compression, and the temperature is generally very high. This is an inevitable phenomenon and not an anomaly 12. If there is a power outage or use of the air compressor during operation, please cut off the power supply to ensure safety

-

2022-10-12 Pressure regulation method of piston compressor

2022-10-12 Pressure regulation method of piston compressor1. Adjustment of pressure level: Turn the pressure adjustment screw 1 clockwise to increase the applied pressure, and vice versa to decrease the applied pressure, but the pressure difference remains unchanged 2. Adjustment of pressure level: Turn the pressure adjustment screw 2 clockwise to increase the applied pressure, and vice versa to decrease the applied pressure, but the pressure difference remains unchanged 3. When the air compressor reaches the set pressure, the saturation and relief valves will discharge the gas inside the steel pipe, which is a normal phenomenon and not a leakage 4. 1-2 adjustment screws are interrelated 5. Adjust the pressure to ensure that it exceeds the discharge pressure of the compressor

-

2022-10-12 What is a compressor?

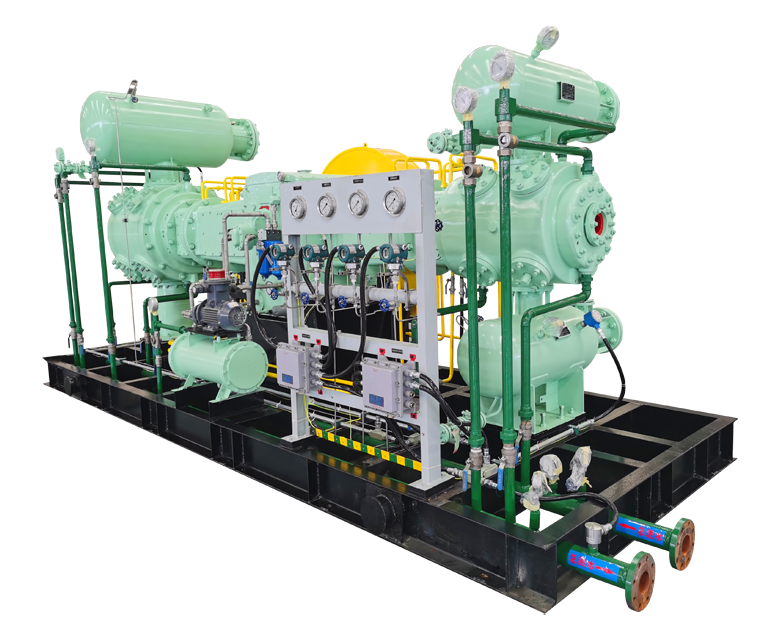

2022-10-12 What is a compressor?The compressor is regarded as the heart of the refrigeration system, and the specialized term that can represent the characteristics of the compressor is called a "vapor pump". The actual responsibility of the compressor is to increase the pressure and raise the suction pressure state to the discharge pressure state. Compression ratio is a technical representation of pressure difference, which means the pressure on the high-pressure side divided by the pressure on the low-pressure side. The calculation of compression ratio must use pressure values. To avoid negative values in the compression ratio calculation, pressure must be used instead of gauge pressure when calculating the pressure ratio. Only by using pressure values can the calculated compression ratio be positive, which is meaningful. There are five types of compressors used in the refrigeration and air conditioning industry: reciprocating, screw, rotary, vortex, and centrifugal. Among them, reciprocating is a commonly used compressor in small and medium-sized commercial refrigeration systems. Screw compressors are mainly used in large commercial and industrial systems. Rotary compressors and scroll compressors are mainly used in household and small capacity commercial air conditioning units, while centrifugal compressors are widely used in air conditioning systems for large buildings. Various reciprocating compressors are generally classified according to the form of the compressor housing and the setting of the driving mechanism. According to the shell form, there are open and closed semi closed compressors. Closed type refers to the entire compressor being housed within a single casing.

-

2022-10-12 Classification Introduction of Compressors

2022-10-12 Classification Introduction of CompressorsCompressors can be divided into volumetric compressors and velocity compressors according to their principles. Volumetric compressors are divided into reciprocating compressors and rotary compressors; Speed compressors are divided into axial compressors, centrifugal compressors, and mixed flow compressors. Nowadays, compressors for household refrigerators and air conditioners are of the positive displacement type, which can be further divided into reciprocating and rotary types. Reciprocating compressors use piston, crank, connecting rod mechanisms or piston, crank, sliding tube mechanisms, while rotary compressors mostly use rolling rotor compressors. In commercial air conditioning, there are mostly centrifugal, vortex, and screw types. According to the application scope, it can be divided into low back pressure type, medium back pressure type, and high back pressure type. Low back pressure (evaporation temperature -35~-15 ℃), generally used for household refrigerators, food freezers, etc. Medium back pressure type (evaporation temperature -20~0 ℃), generally used for cold drink cabinets, milk refrigerators, etc. High back pressure type (evaporation temperature -5~15 ℃), generally used for room air conditioners, dehumidifiers, heat pumps, etc.